PRODUCT OVERVIEW

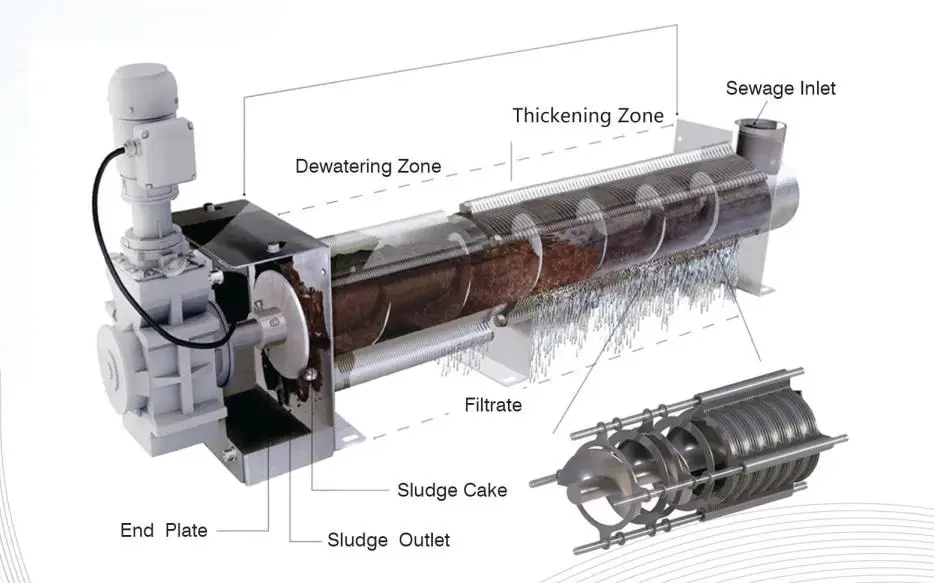

SCREW PRESS SLUDGE DEWATERING MACHINE

Following the principles of the same direction of force water, thin layer dewatering, proper pressure and extension of dewatering path, SANSHINE screw dewatering machine solves the technical problems of the previous generations of sludge dewatering equipment, such as easy blockage, unable to deal with low concentration sludge and oily sludge, high energy consumption and complex operation, and achieves the dehydration goal of high efficiency and energy saving.

FEATURES AT A GLANCE

COVER A SMALL AREA

24 HOURS AUTOMATIC RUNNING

LOW POWER CONSUMPTION

ENERGY SAVING

LOW RUNNING FAILURE RATE

LOW INVESTMENT COST

SIMPLE REQUIREMENTS FOR ACCESSORIES

SIMPLE CONTROL

EASY MAINTENANCE

00:0000:45

PRODUCT SPECIFICATIONS

|

Model

|

Dry Sludge Capacity

(kg-DS/h)

|

Sludge Treating Capacity

(m3/h)

|

|

Low-high Concentration

|

2000mg/L

|

10000mg/L

|

20000mg/L

|

30000mg/L

|

40000mg/L

|

50000mg/L

|

|

HDL-131

|

4~14

|

2

|

0.6

|

0.5

|

0.4

|

0.3

|

0.28

|

|

HDL-132

|

8~28

|

4

|

1.2

|

1

|

0.8

|

0.6

|

0.56

|

|

HDL-201

|

8~20

|

4

|

1.2

|

0.75

|

0.6

|

0.5

|

0.4

|

|

HDL-202

|

16~40

|

8

|

2.4

|

1.5

|

1.2

|

1

|

0.8

|

|

HDL-203

|

24~60

|

12

|

3.6

|

2.25

|

1.18

|

1.5

|

1.2

|

|

HDL-301

|

20~70

|

10

|

3

|

2.5

|

2

|

1.5

|

1.4

|

|

HDL-302

|

40~140

|

20

|

6

|

5

|

4

|

3

|

2.8

|

|

HDL-303

|

60~210

|

30

|

9

|

7.5

|

6

|

4.5

|

4.2

|

|

HDL-304

|

80~280

|

40

|

12

|

10

|

8

|

6

|

5.6

|

|

HDL-351

|

40~120

|

20

|

6

|

5

|

4

|

3

|

2.4

|

|

HDL-352

|

80~240

|

40

|

12

|

10

|

8

|

6

|

4.8

|

|

HDL-353

|

120~360

|

60

|

18

|

15

|

12

|

9

|

7.2

|

|

HDL-354

|

160~480

|

80

|

24

|

20

|

16

|

12

|

9.6

|

|

HDL-401

|

67.5~160

|

33.7

|

10

|

6.5

|

5

|

4

|

3.2

|

|

HDL-402

|

135~320

|

67.5

|

20

|

13

|

10

|

8

|

6.4

|

|

HDL-403

|

200~480

|

100

|

30

|

19.5

|

15

|

12

|

9.6

|

|

HDL-404

|

266~640

|

133

|

40

|

26

|

20

|

16

|

12.8

|

STRUCTURE PRINCIPLE

PRODUCT CONFIGURATION

Flocculation Tank

Connecting Pipe

UPVC Tube

PROCESSING FLOW

APPLICATION AREA

FAQ

Q: Can the screw type sludge dehydrator be placed outside?

A: Yes, the protective performance of the corresponding electric cabinet and motor needs to be improved. For example, the motor needs to add rainproof cover, motor protection IP55, IP65, etc

Q: Is the mud removed from our equipment shipped directly?

A: Yes, the mud can be shipped directly.

Q: What kind of sludge is the screw type sludge dehydrator suitable for?

A: The dehydrator is a multi-plate solid-liquid separator, which is suitable for most occasions requiring solid-liquid separation, as long as the particles can be flocculated into particles larger than 0.25mm.

Q: Does screw type sludge dehydrator need to add medicine?

A: Yes, it is necessary to add flocculants to sludge to form alum flower with certain particle size and strength to enter the main body of the dehydrator for dewatering.

Q: Can screw type sludge dehydrator be self-cleaned to avoid blockage without backwash pump?

A: Yes, during operation, the swimming ring is in constant motion and has the function of self-cleaning filter joint to prevent clogging.

Q: What are the advantages of screw type sludge dehydrator compared with traditional filter press?

A: 1. Good at handling oily sludge; 2. Compact design, saving space; 3. Simple operation and maintenance; 4. Save electricity & water; 5. Low noise, low vibration

Q: How long is your warranty?

A: One year after the arrival of the goods. During this period, as long as it is not a man-made damage, we send the damaged parts for free

Q: What about your delivery time?

A: Normally within 30 days against down payment.