Energy saving dehydration equipment for waste water treatment screw press

Model No.︰HDL-402

Brand Name︰Sanshine

Country of Origin︰-

Unit Price︰US $ 37150 / set

Minimum Order︰1 set

Product Description

Product Description

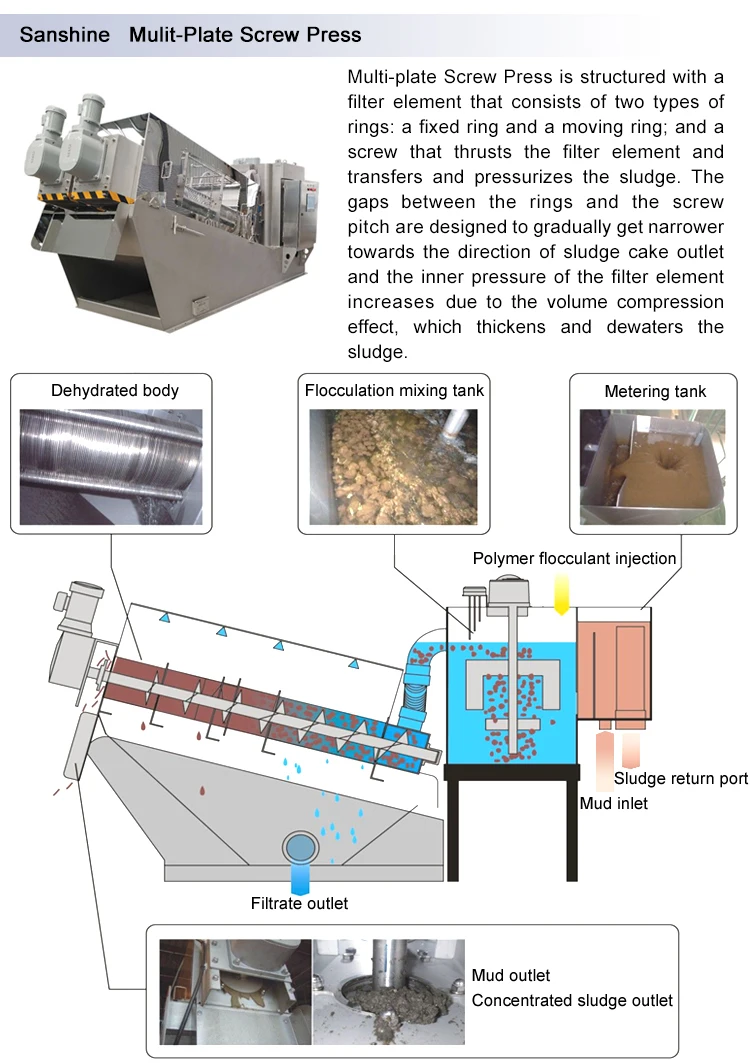

Mulit-Plate Screw Press Sludge Dewatering Introduction

The screw sludge dewaterinng machine belongs to the screw press, it's clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. Using screw and the moving rings to clean itself as clog-free structure, and controlled by the PLC automatically, it's a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.It concentrates and dehydrates sewage directly in 24 hours continuously and efficiently with self-service operating and greatly reduces the cost of design,construction,operation maintenance and management.

Mulit-Plate Screw Press Advantanages

| 1.No filter cloth, no clogging. |

| 2.self-cleaning mechanism. |

| 3.Wide range of line-up and small footprint. |

| 4.Thickening and dewatering all in one filter drum. |

| 5.Compact design with flocculation and dewatering. |

| 6.Applicable to sludge in various kinds of application. |

| 7.Automatic operation and easy maintenance,Low operation cost. |

| 8.Environment friendly(Power Saving ,Water Saving,No vibration and noise) |

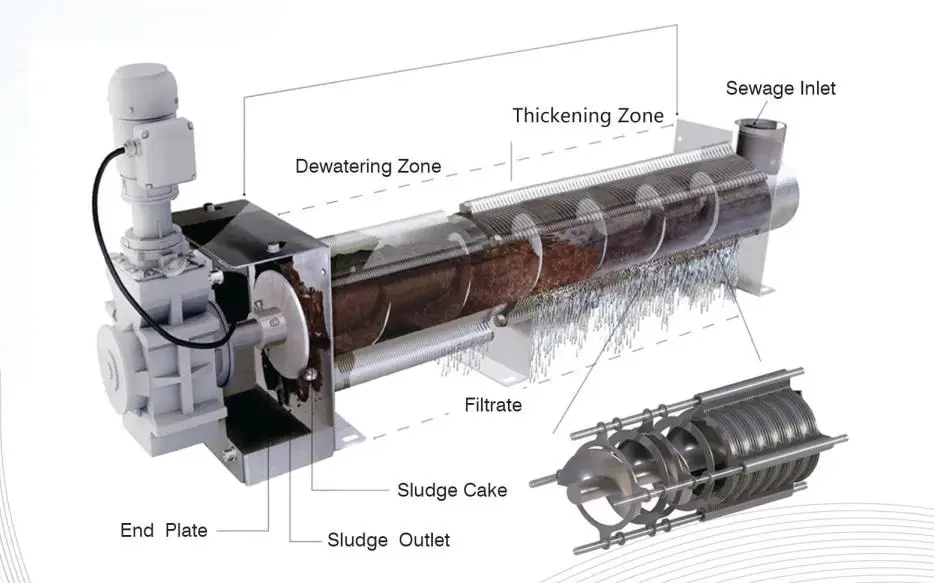

Structure Principle

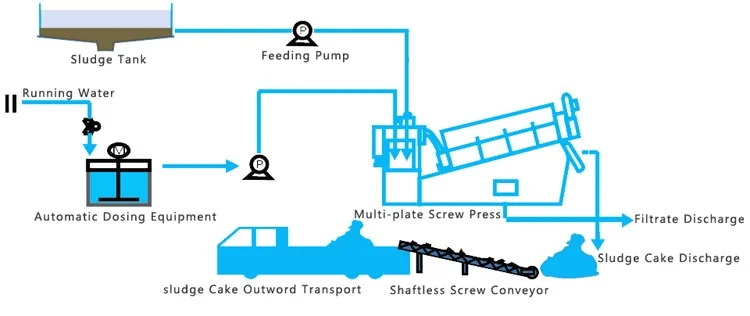

Processing Flow

Sludge,first fed into the flow control tank,flows into the flocculation tank where polymer coagulant is added.from there,the flocculated sludge overflows into the dewatering drum where it is filtered and compressed. The entire operation sequence, including sludge feed control,polymer makeup,dosing and sludge cake discharging,is controlled by the built-in timer and sensors of the control panel.

Model reference

Please advise us the sludge source, treating capacity, solid content rate, then we could choose the suitable model for you.

| Model |

Dry Solids Capacity (kg-DS/h) |

Sludge Treatment Capacity(m3/h) | |||||

|

Low-High Concentration |

2000mg/L | 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | |

| HDL-101 | 2~7 | 1 | 0.3 | 0.25 | 0.2 | 0.15 | 0.14 |

| HDL-131 | 4~14 | 2 | 0.6 | 0.5 | 0.4 | 0.3 | 0.28 |

| HDL-132 | 8~28 | 4 | 1.2 | 1 | 0.8 | 0.6 | 0.56 |

| HDL-201 | 8~20 | 4 | 1.2 | 0.75 | 0.6 | 0.5 | 0.4 |

| HDL-202 | 16~40 | 8 | 2.4 | 1.5 | 1.2 | 1 | 0.8 |

| HDL-203 | 24~60 | 12 | 3.6 | 2.25 | 1.8 | 1.5 | 1.2 |

| HDL-301 | 20~70 | 10 | 3 | 2.5 | 2 | 1.5 | 1.4 |

| HDL-302 | 40~140 | 20 | 6 | 5 | 4 | 3 | 2.8 |

| HDL-303 | 60~210 | 30 | 9 | 7.5 | 6 | 4.5 | 4.2 |

| HDL-304 | 80~280 | 40 | 12 | 10 | 8 | 6 | 5.6 |

| HDL-351 | 40~120 | 20 | 6 | 5 | 4 | 3 | 2.4 |

| HDL-352 | 80~240 | 40 | 12 | 10 | 8 | 6 | 4.8 |

| HDL-353 | 120~360 | 60 | 18 | 15 | 12 | 9 | 7.2 |

| HDL-354 | 160~480 | 80 | 24 | 20 | 16 | 13 | 9.6 |

| HDL-401 | 67.5~160 | 33.7 | 10 | 6.5 | 5 | 4 | 3.2 |

| HDL-402 | 135~320 | 67.5 | 20 | 13 | 10 | 8 | 6.4 |

| HDL-403 | 200~480 | 100 | 30 | 19.5 | 15 | 12 | 9.6 |

| HDL-404 | 266~640 | 133 | 40 | 26 | 20 | 16 | 12.8 |

Application Area

| Mulit-plate Screw Press Applies To Many Kinds of Industries | |

| Rubber industry | Gelatin industry |

| Paper making | Textile industry |

| Food industry | Kitchen waste |

| Coal chemical industry | Eletroplating industry |

| Printing and dyeing | Machining wastewater |

| Water purification industry | Marsh gas / methane |

| Industrial wastewater | Petrochemical industry ( oily sludge) |

| Animal husbandry / livestock industry | Pharmaceuticals industry / pharmacy |

| Recycled water / reclaimed water | Animal slaughter / animal butcher |

| Municipal wastewater / domestic wastewater | Biotechnology / bioengineering |

| Refuse processing plant / garbage proposal | Landfill leachate / refuse leachate |

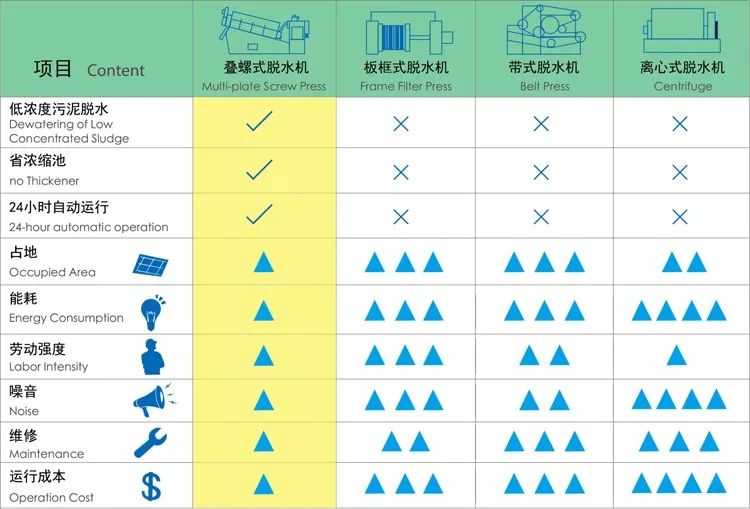

Comparison Chart

Our Exhibition

Certifications

Payment Terms︰ TT / LC

Product Image